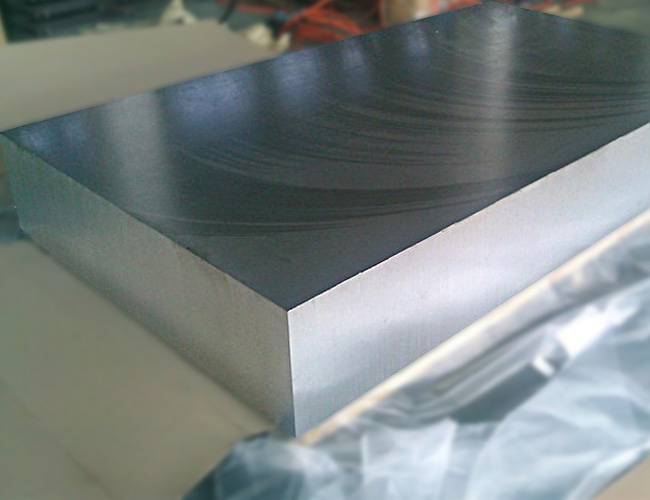

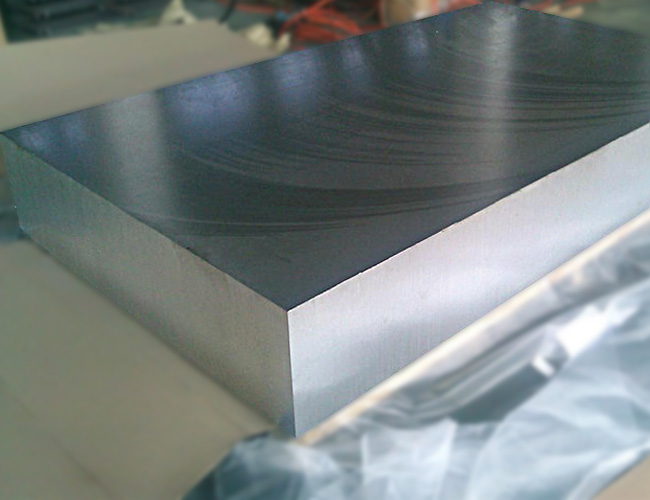

Marine grade aluminum plate

Marine grade 5083H32/5083-H116 aluminum plate /Marine plates and LNG plate

Marine aluminum plate is the emerging market for R & D applications of aluminum products. Shipboard production capacity has also become an important indicator of the comprehensive strength of various aluminum processing enterprises. With the upgrading of domestic aluminum production process, leading enterprises in Henan Province - Haomei Aluminum Plate production scale gradually expanded, increasingly rich types of alloys, product performance has reached the international advanced level.At present, Haomei 5083 aluminum plate, 5086 aluminum plate, 5754 aluminum plate and other products, has entered the world shipbuilding market, mainly used in the ship's deck, the engine platform, the ship side, the bottom of the ship and other components.

Marine aluminum alloy plate is one of the emerging areas of aluminum products, but also the transformation and upgrading of many domestic aluminum processing enterprises focus on the direction. Marine aluminum alloy because it is used for marine ships and other fields, so than other

| Aluminum Grade-Temper | General | Yield strength (psi) | Ultimate Tensile Strength (psi) | Workability | Weldability |

| 5052-H32 | Marine grade. Most suited for forming operations, very good corrosion resistance. Suitable for fresh water and trailered boats. | 28,000 | 33,000 12% elong. | Fair | Good |

| 5083-H321 (Interchangeable With: H111 & H116) | Marine grade. The highest strength non-heat-treatable aluminum alloy in commercial use. It retains excellent tensile strength in the weld zone. Excellent corrosion resistance. Suitable for salt water or fresh | 33,000 | 46,000 16% elong. | Good | Excellent |

| 5086-H32 | Marine grade. Medium to high strength non-heat-treatable alloy. More formable than 5083. Excellent corrosion resistance. Most often used to build boat hulls (in addition to 5052 or 6061) due to stress corrosion cracking resistance. Best alloy for salt water. | 30,000 | 42,000 12% elong. | Excellent | Good |

| 6061-T6 | Marine grade, often used as stiffeners to build boat hulls and other components. The most often used aluminum alloy for its strength, heat treatability, workability and weldability. | 40,000 | 45,000 17% elong. | Good | Good |

| 6063-T52 | Softer and lower strength than 6061, good for forming, high surface finish, excellent for anodizing. Good for railings, gunnels etc. where forming is required | 21,000 | 27,000 | Good | Good |

| 6262-T6511 | Used when significant machining is required, it contains lead and bismuth to partially lubricate the cutting tool. Good strength and corrosion resistance. High surface finish possible. | 27,600 | 31,900 | Excellent | Good |