Powder Coated Aluminum Tread Plate

2026-01-27 10:34:22

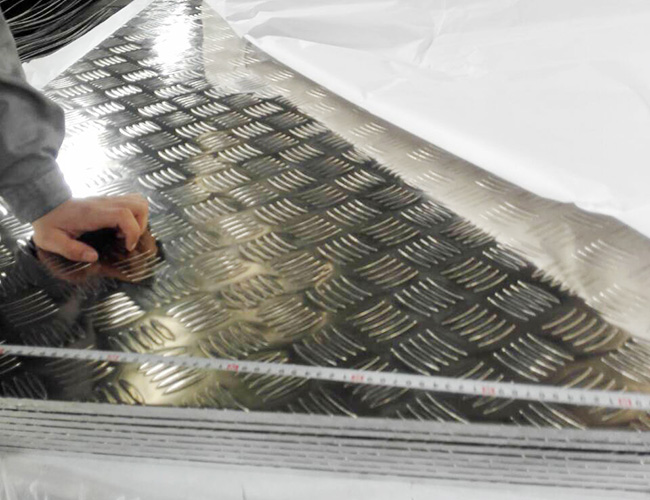

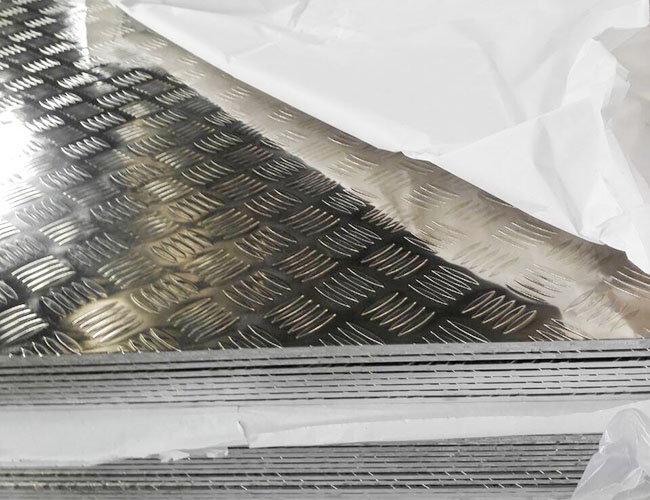

Powder Coated Aluminum Tread Plate (also known as aluminum diamond plate or checker plate) combines a raised tread pattern with a tough powder-coated finish. The result is a lightweight, corrosion-resistant, slip-resistant metal sheet that looks professional and performs reliably in demanding environments.

Whether you need safer walking surfaces, clean-looking truck and trailer panels, or a rugged material for industrial fabrication, this tread plate offers strong grip, easy maintenance, and long service life.

Key Parameters (Specifications)

Material: Aluminum alloy (common options: 3003, 5052, 6061)

Surface: Powder coated (standard or custom colors available)

Pattern: Tread plate (diamond/checkered pattern; pattern height varies by spec)

Thickness: Typical range 1.0 mm to 6.0 mm (custom available)

Width: Common 1000 mm, 1200 mm, 1250 mm (custom available)

Length: Common 2000 mm, 2440 mm, 3000 mm (custom available)

Temper: H14/H22/H32/T6 depending on alloy and application

Coating thickness: Typically 60-100 μm (custom available)

Finish options: Matte, satin, textured, anti-scratch (based on powder selection)

Note: If you share your intended use (outdoor marine, heavy foot traffic, vehicle flooring, etc.), we can recommend the best alloy/temper and coating system.

Purpose and Applications

Powder coated aluminum tread plate is designed to improve traction, durability, and appearance in one material.

Popular uses include:

- Vehicle and transportation: truck beds, trailer floors, RV steps, toolboxes, ramps

- Construction and infrastructure: stair treads, catwalks, platforms, access covers

- Industrial and warehouse: anti-slip flooring, machine guards, workstations

- Marine and outdoor projects: docks, gangways, coastal structures (with suitable alloy/coating)

- Architectural and interior: wall panels, decorative cladding, retail fixtures

Packaging and Delivery

We package to protect both the coating surface and the raised tread pattern during transit.

Standard packaging options:

- Protective film (optional) to reduce scuffing and handling marks

- Waterproof paper + edge protectors

- Strong export-grade wooden pallets/crates

- Steel strapping and corner guards to prevent shifting

- Clear labeling: alloy, temper, thickness, coating color code, batch/heat number

Shipping forms:

- Sheets (most common for tread plate)

- Cut-to-size pieces (for reduced fabrication time and waste)

Advantages (Why Buyers Choose Powder Coated Tread Plate)

1) Better corrosion and weather protection

Powder coating forms a durable barrier against moisture, road salts, and general outdoor exposure (system selection matters for harsh environments).

2) Slip-resistant raised pattern

The tread pattern improves traction for safer steps, walkways, ramps, and vehicle flooring.

3) Lightweight but strong

Aluminum is significantly lighter than steel, supporting easier installation and lower transport load while still providing excellent rigidity.

4) Clean, consistent appearance

Powder coating delivers uniform color and a premium finish for visible applications like trailers, architectural panels, and shop builds.

5) Lower maintenance

The coated surface is easier to clean and helps reduce staining and oxidation compared to uncoated aluminum.

FAQs

Q1: What is the difference between powder coated and mill finish aluminum tread plate?

Powder coated tread plate adds a protective, colored layer for improved corrosion resistance and appearance. Mill finish is uncoated and may show natural oxidation and surface marks more easily.

Q2: Which alloy is best for outdoor or marine environments?

Commonly, 5052 is preferred for better corrosion resistance, while 6061 offers higher strength (with different forming behavior). Tell us your exposure conditions and load requirements for the best match.

Q3: Can I order custom colors?

Yes. Custom colors can be produced (including RAL options). Matching requirements may affect MOQ, lead time, and cost.

Q4: Will the coating reduce slip resistance?

The tread pattern provides the main traction. Many powder systems maintain grip well, and textured powders can further enhance anti-slip performance.

Q5: How do I cut or fabricate powder coated tread plate without damaging the finish?

Use clean cutting tools, protect the surface with film where possible, and deburr edges carefully. For drilling/fastening, use proper bits and consider edge sealing in harsh environments.

Q6: What information should I provide for an accurate quote?

Thickness, sheet size or cut list, alloy/temper, coating color/finish, quantity, end-use environment, and delivery port/address.

Request a Quote or Custom Spec

If you need anti-slip, corrosion-resistant, visually consistent tread plate, Powder Coated Aluminum Tread Plate is a reliable, high-value choice. Share your thickness, size, and color requirements, and we will recommend the best alloy and coating system for your application.