Mill Finish Aluminum Tread Sheet

2026-01-27 10:34:13

Brief Introduction

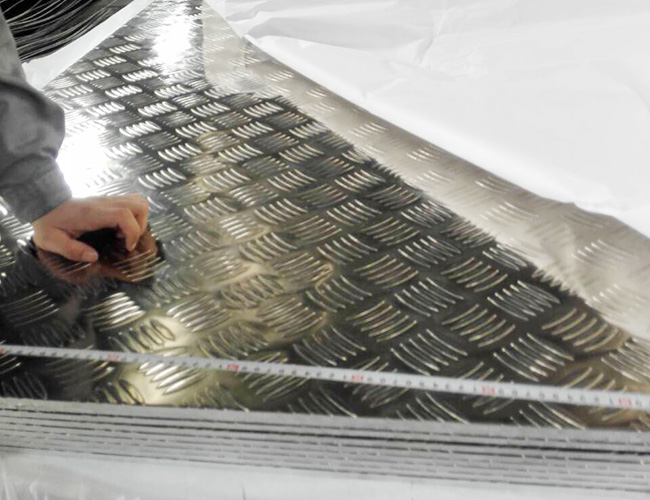

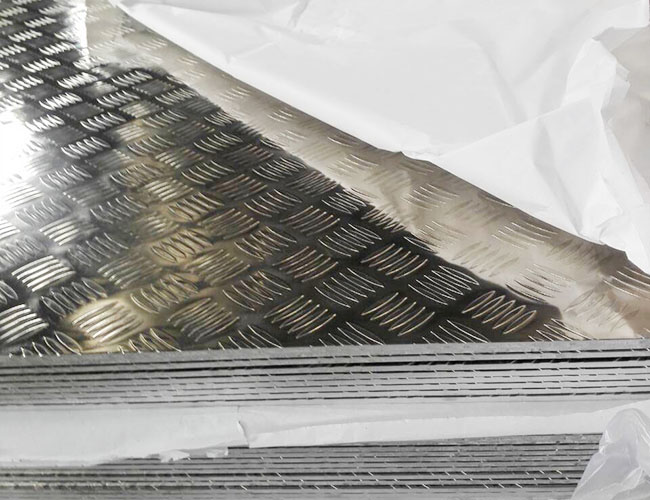

Mill Finish Aluminum Tread Sheet (also called aluminum tread plate or checker plate) is a patterned aluminum sheet designed to improve traction while keeping weight low. The raised bars deliver reliable slip resistance for walking surfaces, loading areas, and industrial platforms, while the mill finish surface maintains a clean, natural metallic appearance that is easy to maintain.

Key Parameters (Specifications)

Note: We can supply multiple sizes and alloys. The following ranges cover common market requirements.

Material & Temper

- Alloy options (common): 1060, 3003, 5052, 6061 (based on strength and corrosion needs)

- Temper options: O, H12, H14, H16, H18, H22, H24, T4, T6 (depending on alloy)

Surface & Pattern

- Surface: Mill finish (natural aluminum, non-coated)

- Pattern types: 5-bar / diamond / propeller (availability depends on thickness and alloy)

Dimensions

- Thickness (typical): 1.0 mm to 6.0 mm (other thicknesses available)

- Width (typical): up to 1500 mm

- Length (typical): up to 6000 mm

- Form: sheet or coil (patterned sheet is commonly supplied as sheets)

Fabrication Compatibility

- Cutting: shearing, sawing, laser (alloy/thickness dependent)

- Forming: bending and rolling (best with appropriate temper)

- Joining: riveting and bolting; welding possible with suitable alloy selection

Purpose and Typical Applications

Mill finish aluminum tread sheet is chosen when you need slip-resistant surfaces, lightweight construction, and corrosion resistance.

Common uses include:

- Trailers and truck bodies: floors, steps, tailgates

- Industrial flooring: catwalks, platforms, mezzanines

- Ramps and stair treads: safer walking surfaces

- Marine and outdoor structures: docks, walkways, equipment covers

- Toolboxes and vehicle upfits: panels and protective linings

- Architectural protection: wall guards, kick plates, utility panels

Packaging (Safe Shipping and Storage)

To protect the raised pattern and keep sheets flat during transit, standard export packaging is used:

- Waterproof paper + protective film (optional) to prevent moisture stains and scratches

- Corner protectors to reduce edge damage

- Wooden pallets or wooden crates with steel/PP strapping

- Fumigation or non-fumigation pallets available for export compliance

- Clear labeling: alloy, temper, thickness, size, batch/heat number

Tip for storage: Keep sheets in a dry, ventilated area and avoid direct contact with wet concrete or corrosive chemicals.

Advantages (Why Buyers Choose Mill Finish Aluminum Tread Sheet)

- Anti-slip performance: raised bars increase grip and improve safety on walkways and ramps

- Lightweight but strong: aluminum reduces overall structure weight vs. steel

- Corrosion resistance: suitable for humid, outdoor, and many industrial environments

- Easy to fabricate: cut, drill, bend, and install with standard metalworking tools

- Low maintenance: mill finish surface is easy to wipe clean

- Cost-effective: long service life with reduced upkeep and replacement needs

FAQ

Q1: What does “mill finish” mean? Mill finish is the natural aluminum surface as produced by rolling, without anodizing or painting. It may show slight rolling marks and has a clean metallic look.

Q2: Which alloy is best for general-purpose tread plate?

- 3003 is widely used for general fabrication with good corrosion resistance.

- 5052 is preferred for stronger corrosion resistance (especially marine or coastal environments).

- 6061 is chosen when higher structural strength is needed.

Q3: Is aluminum tread sheet suitable for outdoor use? Yes. Aluminum naturally forms an oxide layer that helps resist corrosion. For harsh environments, choosing 5052 or adding surface treatment can extend service life.

Q4: Can I cut and bend the tread sheet? Yes. Cutting is straightforward. Bending depends on alloy and temper; softer tempers bend more easily. Share your bending radius and thickness requirements for the best recommendation.

Q5: What pattern should I choose (5-bar vs. diamond)?

- 5-bar is popular for modern appearance and comfortable footing.

- Diamond is a classic industrial look with strong traction.

Q6: How do you prevent scratches during shipping? We use protective interleaving, optional film, edge guards, and reinforced pallet/crate packing to protect the raised pattern and surface.

Ready to Order

Send your required alloy, temper, thickness, sheet size, quantity, and application (flooring, trailer, ramp, marine, etc.). We will recommend the best mill finish aluminum tread sheet specification for strength, corrosion resistance, and budget.