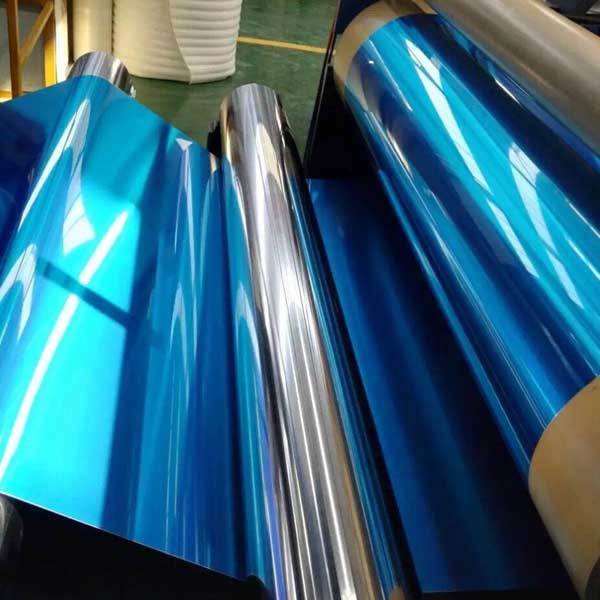

PVDF Color Coated Aluminum Coil

PVDF Color Coated Aluminum Coil :made of fluorine carbon resin,

pigment, ester solvent, after high temperature roasting and baking, the

paint is solidified to dry film with super weather resistance. PVDF

coating also can be classified as traditional PVDF and nanometer PVDF

coating.

A.Traditional PVDF Coating, with KYNAR500 PVDF, two or three times for

coating and baking, has good properties of anti-acid, anti-alkali and is

durable in atrocious weather and environment, keeping 15 years no

unwonted fading. In view of these facts, we recommend this panel applied

for external wall cladding.

B.Nanometer PVDF Coating, which different with traditional PVDF is the

clear coating. It contains nanometer element, which can protect panel

from pollution, Because nanometer has self-cleaning effect, It easy to

get rid of dust and pollution by raining or water.

Parameters of PVDF Color Coated Aluminum Coil

Substrates: | Aluminium (AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc. |

Thickness: | 0.08-1.5mm |

Width: | <1800mm |

Coils core diameter: | 150mm ,405mm, 505mm, 508mm, 510mm |

Coating thickness: | PVDF >=25micron POLYESTER>=18micron |

Color standard: | E < 2 or it is not obvious by eyeballing |

Pencil hardness: | > 2HB |

Coating adhesive: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

Bend stength: | >100 times |

Boiling point: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: | surface deep in the 5% muriatic acid and 5% NaCL, interior deepin the 2% muriatic acid and 2% NaCL, after 48 hours, no change |