Aluminium Circles Latest Price

2026-02-03 09:07:21

Brief Introduction

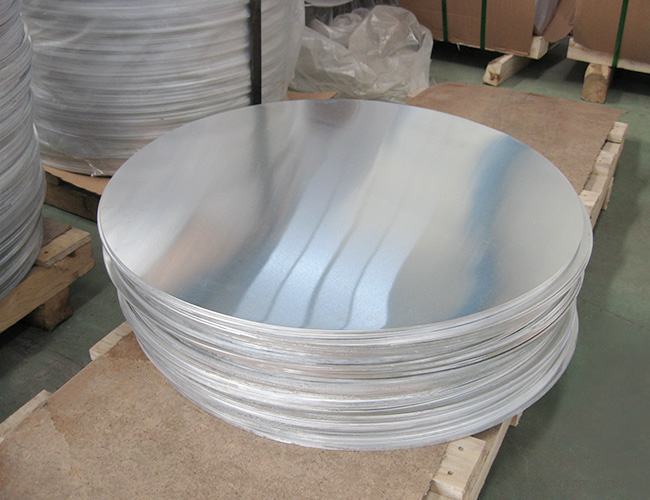

If you are comparing Aluminium Circles latest price for cookware, lighting, or deep drawing parts, the most important thing is not just the number per ton, but what is included in that price: alloy and temper, thickness tolerance, surface quality, edge condition, and the consistency that reduces your press waste.

Our aluminium circles (also called aluminium discs) are produced from high-quality coils, precisely blanked for smooth edges and reliable forming. They are widely used for spinning, deep drawing, stamping, and anodizing.

Parameters (Specifications)

Below is a practical specification range for ordering and quotation. Final specs can be customized to your drawing and forming process.

Standard Product Specs

- Product name: Aluminium Circles / Aluminium Discs

- Alloys: 1050, 1060, 1070, 1100, 3003, 8011 (others available on request)

- Temper: O (soft), H12/H14/H16/H18 (as required)

- Thickness: 0.3 mm to 6.0 mm (common range)

- Diameter: 80 mm to 1200 mm (common range)

- Surface: Mill finish (standard), anodizing-quality surface available

- Edge: Clean cut, burr-controlled, suitable for spinning and deep drawing

- Production process: Coil → leveling → punching/blanking → deburring (if required) → inspection → packing

Recommended Alloys by Application

- 1050/1100 (high purity): Excellent forming, anodizing, reflectivity; ideal for cookware and lighting reflectors

- 3003 (Mn alloy): Better strength than 1xxx series; good for deeper drawing and stronger end products

- 8011: Often used for general stamping/forming needs depending on customer spec

Aluminium Circles Latest Price: What Influences the Quote?

Because aluminium is a commodity-based metal, the latest price typically changes with the market. Your final quote is usually affected by:

- Aluminium ingot price (LME/SHFE trends)

- Alloy and temper (e.g., 1050-O vs 3003-H14)

- Thickness and diameter (material utilization and punching yield)

- Surface quality requirement (cookware/anodizing grade requires stricter control)

- Tolerance and flatness (tighter tolerances increase processing/inspection)

- Quantity (MOQ) and order frequency

- Packaging and export requirements (pallet, moisture barrier, wooden crate)

- Delivery terms (EXW/FOB/CIF) and destination

Tip for buyers: When comparing aluminium circle price between suppliers, confirm whether the quote includes edge deburring, surface grade, and diameter tolerance. These directly impact scrap rate and forming speed.

Purpose (Applications)

Aluminium circles are designed for fast, consistent forming and finishing across multiple industries:

- Cookware: pots, pans, pressure cooker parts, lids

- Lighting: lampshades, reflectors, LED housings

- Industrial spinning: spun parts, covers, shells

- Electrical & electronics: capacitor cases, housings

- Signage & decoration: nameplates, discs for anodizing/coloring

- Automotive & hardware: stamped and drawn components

Packaging (Export-Safe Options)

To protect circles from moisture, oxidation, and edge damage during handling and sea shipment, we offer standard and upgraded packing:

Standard Packaging

- Circles stacked by size

- Inner protection film or interleaving paper (optional)

- Moisture barrier wrap

- Steel-strapped to fumigation-free pallets

Export Reinforced Packaging (Recommended)

- Strong outer carton + pallet or wooden crate

- Corner protectors and extra strapping

- Desiccant packs for long ocean routes

Labeling: alloy, temper, thickness, diameter, batch number, net/gross weight for traceability.

Advantages (Why Buyers Choose These Aluminium Circles)

- Stable forming performance

- Consistent grain and controlled hardness support deep drawing and spinning.

- Clean edges, lower rejection rate

- Burr-controlled edges help reduce tool wear and improve safety.

- Surface quality for cookware/anodizing

- Cleaner surface reduces polishing time and improves final appearance.

- Flexible alloy options

- Choose 1050/1100 for maximum ductility, or 3003 for improved strength.

- Cost efficiency beyond the latest price

- Better yield and less downtime often lowers your true cost per finished part.

FAQ

1) What is the best alloy for cookware aluminium circles?

For most cookware, 1050-O or 1100-O is widely used due to excellent forming. If you need higher strength or better dent resistance, consider 3003.

2) Do you provide anodizing-quality aluminium circles?

Yes. We can supply circles with controlled surface quality suitable for anodizing and decorative finishing. Share your finishing requirement and acceptable defect standard.

3) How do I get the Aluminium Circles latest price quickly?

Send these details for a fast, accurate quote: alloy, temper, thickness, diameter, quantity, application (spinning/deep drawing), surface requirement, and delivery term (FOB/CIF).

4) What tolerances can you meet?

Tolerance depends on thickness/diameter and application. If you have a drawing or target tolerance, we can match it and confirm in the quote.

5) Can you customize packaging for export?

Yes. We offer pallet, carton, and crate options with moisture protection and labeling for warehouse scanning and batch traceability.

Request a Quote (Recommended Information)

To lock in a competitive aluminium circle price and reduce back-and-forth, please provide:

- Alloy/temper (e.g., 1050-O, 1100-O, 3003-H14)

- Thickness and diameter range

- Monthly/annual demand

- End-use process (deep drawing/spinning/stamping)

- Surface grade requirement (cookware/anodizing/standard)

- Destination port and trade term (EXW/FOB/CIF)