Alu Alu Foil

Alu alu foil, also called cold forming foil, or cold-form foil, is a kind of high barrier property of composite material, after cold stamping molding, can replace the PVC part of PTP blister packaging, which could greatly improve the protective for drugs(tablets,pills and capsules), extend the shelf life.

Alu alu foil is the best composite film of blocking performance at present with ultimate protection against water, oxygen and UV radiation.It is especially used for the high sensitive range of pharmaceutical and generic medicines which are highly hygroscopic or light sensitive.

Alloy8021

TemperSoft or O

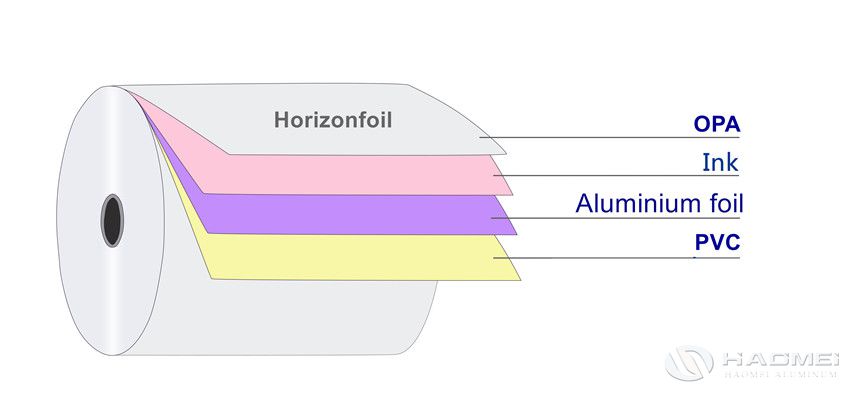

StructureOPA/Al/PVC

ThicknessOPA: 25mics Al: 45~60mics PVC: 60mics

PrintingUnprinted or 1~4 colors printing as required

WidthCustomized from 60mm to 700mm

Inner core ID76mm or152mm

PackingStandard pharmaceutical packing

| STRUCTURE | |||

|---|---|---|---|

| OPA Film | micron | 25 | ±10% |

| Adhesive | g/m2 | 4 | ±8% |

| Aluminum Soft Foil | micron | 45-60 | ±10% |

| Adhesive | g/m2 | 4 | ±8% |

| PVC film | micron | 60 | ±10% |

| Total Thickness | micron | 130-145 | ±10% |

| Total Weight | g/m2 | 250 | ±10% |

Structure of alu alu foil

1st layer: Over lacquer, to protect the printing, ensure the ink fastness and not easy to peel off.

2nd layer: Ink, text and information printing.

3rd layer: Aluminium foil, thickness can be 20mics, 25mics and 30mics

4th layer: Heat seal lacquer, heat seal with PVC, PVDC or other materials.

Features & Advantages of Alu alu foil

Absolutely resist vapor, oxygen and uv rays with good performance of aroma barrier.

Excellent properties of anti-oxygen, moisture-proof, hygiene and bacterium-resistance.

Strong intensity, excellent malleability, not easily crumbled.

Fine seal performance.

Applications of Alu alu foil

Replace the PVC part of blister packaging.

Suitable to pack drugs that easy to be affected in wet regions and tropics.

Used for high standard pharmaceutical packaging for pills, tablets, powder, suppositories, capsule